X-Ray Inspection

Review station

Inline conveyor

AXI 7300

The AXI 7300 is a state-of-the-art inline X-ray inspection system equipped with inlet and outlet conveyors.

The AXI 7300 has advanced features that significantly enhance its capabilities. These include a cutting-edge linear motor transport system that enables quick and accurate object movement, a large inspection area, and a high-resolution FPD. The AXI 7300 model maintains its original offline analysis and inspection mode while connecting to the SMT production line for high-capacity automatic inline full inspection.

The X-ray equipment is a fully shielded radiation enclosure to ensure complete safety. The AXI 7300 is ideal for precise testing in various industries, including SMT, lithium batteries, and precision injection molding. The X and Y axes of the system offer a travel range of 650mm x 550mm, and a specialized module is included to detect bubbles or voids in electronic components with BGA, QFN, or QFP packaging. The system also supports teaching functions for various product inspections. Barcode automatic recognition and automatic report storage are optional add-ons to complete the user friendly software interface.

AXI 7300

| Inspection Area | 635mm x 358mm |

| Maximum 5-axis Tilt | 45° |

| Maximum X-Ray Power | 130kV 5µm |

| X-Ray Flat Panel Detector | 4″x 3″ (5″x5″ Optional) |

| System Magnification | 800x |

| Resolution of Main Camera | 1248×1024 |

| Air Specification | 0.4-0.6 MPa |

| Max Length of Measurable Product | 650mm |

| Max Width of Measurable Product | 500mm |

| Max Height of Measurable Product | 70mm |

AXI 7300

| Automatic Void Percentage Calculation | Yes |

| Barcode | Optional |

| Offline Programming | Yes |

| Repair Station | Yes |

| Discrepancy Comparator | Optional |

| Windows 11 | Yes |

AXI 7300

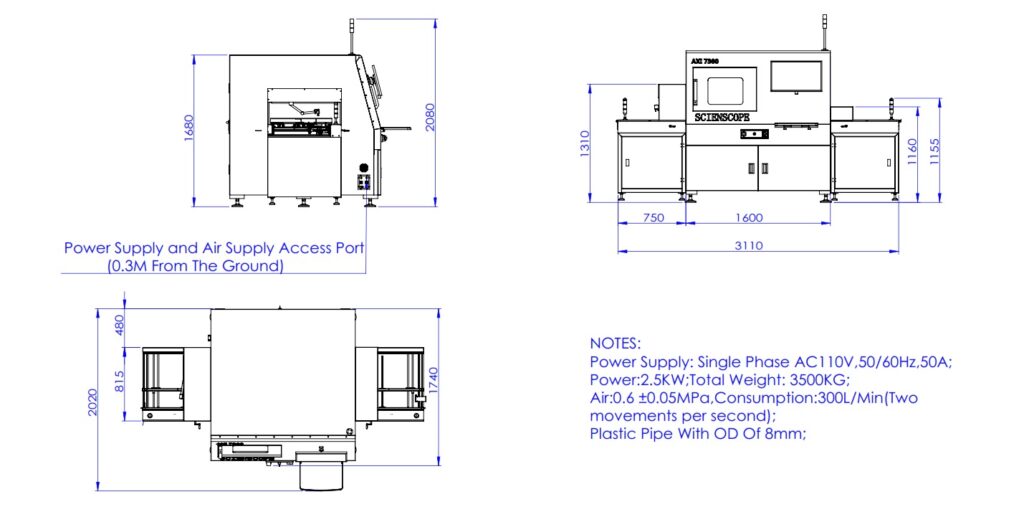

| Dimension | (L/W/H): 1600mm x 1685mm x 1680mm / 62.9″ x 66.3″ x 66.1″ |

| Weight | 3500kg |

| Electric | AC110-240 VAC 50/60Hz |

AXI 7300