The story of Asscon

ASSCON is one of the worldwide leading companies in the field of vapor phase soldering machines. Currently, over 2000 machines are in use on the global market and the customer basis is continuously growing. Specializes in developing and manufacturing vapor phase soldering machines, whereat semi-finished products from different suppliers are assembled in combination with several parts coming from their production. Innovative technology for serial or custom solutions is an essential element of the company’s philosophy. Established in 1995 Germany, this privately owned company has decided to take their custom solutions to the next level with Scienscope’s X-Scope 3000 X-Ray machine.

ASSCON provides vapor phase soldering machines in several dimensions. From laboratory and batch machines to fully inline solutions for serial production. The smallest system like the VP310/VP510 has been developed for laboratory and prototyping purposes. Following by the VP1000-66 which is a representing small series machine and is operational for shift work. For large-scale inline production, the machine series VP2000 offers a suitable solution for nearly every demand.

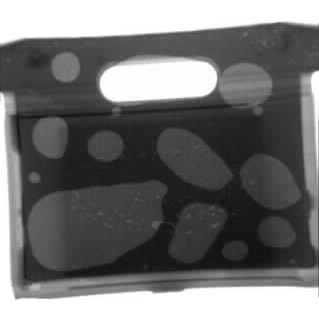

All ASSCON soldering machines are also available with vacuum option, to further increase the resulting solder quality. In 2018 ASSCON installed its first Scienscope product in their application demo center near Munich, Germany. Scienscope helped ASSCON providing customers with the visualization real-time quality of their soldering machines. Scienscope’s X-Ray technology helps during machine demonstration with customers, by proving the reduced void ration directly after the soldering and vacuum process has taken place. The X-Scope 3000 X-Ray is the base of detailed development and quality understanding that ASSCON has provided over the past 20 years.

“The dimension of the X3000 where a small detail but of course a nice advantage to set-up the system. In general, the experience of Scienscope all over the different industries was a key factor to choose Scienscope as a partner. The daily consulting and analysis of high technology-driven customer products is the daily challenge for ASSCON. A partner with a wide range of experience and a leading technology suits perfectly to the request of ASSCON customers,” per ASSCON. “The X3000 is very easy to use due to the very convenient machine software. By having a general understanding of x-ray-technology the operating of the machine is easy to do after a short training. The ASSCON application team is very pleased to use the Scienscope system. All products from customer visits or products which were sent by postal have brilliant results which are again the benefit of the comfortable use of the X3000. “

Other process

Asscon process

The last years have shown an increased demand /interest in manufacturing high-quality products especially in the field of the automotive and lighting industry. Scienscope is helping directly demonstrate how simple and efficient the use of ASSCON vacuum technology can be for the customer which is a big benefit in distributing machines.